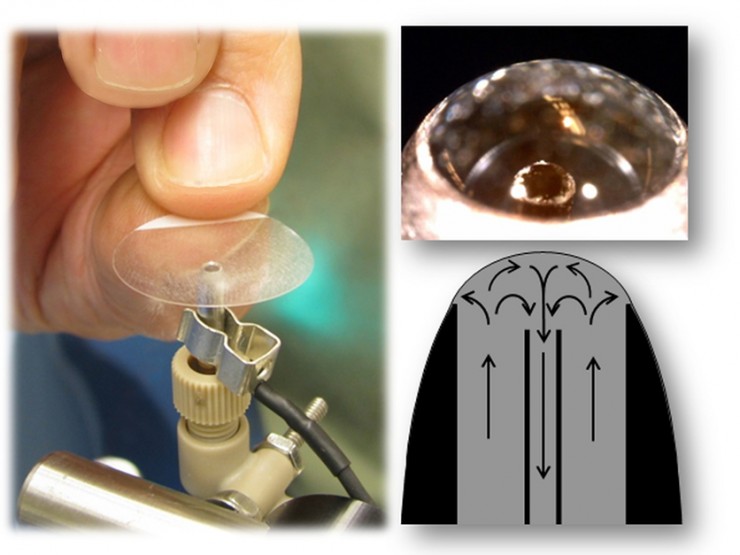

A close-up look at the Open Port Sampling Interfaces for Mass Spectrometry, one of Oak Ridge National Laboratory’s seven 2016 R&D 100 Award winners. (Photo courtesy ORNL)

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have received nine R&D 100 Awards in recognition of their significant advancements in science and technology, a press release said. The honorees were recognized in November at the 55th annual R&D 100 Conference, sponsored by R&D Magazine.

The awards, known as the “Oscars of Invention,†honor innovative breakthroughs in materials science, biomedicine, consumer products, and more from academia, industry, and government-sponsored research agencies. This year’s nine honors bring ORNL’s total of R&D 100 awards to 210 since their inception in 1963, the press release said.

ORNL researchers were recognized for the following innovations:

ACMZ Cast Aluminum Alloys were developed by a team of researchers from ORNL with Fiat Chrysler Automobile U.S. and Nemak U.S.A.

ACMZ aluminum alloys are a new class of affordable, lightweight superalloys capable of withstanding temperatures of almost 100-degree Celsius more than current commercial alloys while providing exceptional thermomechanical performance and hot tear resistance.

Common commercial alloys soften rapidly at high temperatures, limiting their use in next-generation vehicles, while other alloys that can withstand elevated temperatures are cost prohibitive and difficult to cast. ACMZ alloys were developed using a suite of atomic-level characterization and computation tools, resulting in a strong, stable, and versatile material capable of withstanding the stressful conditions of next-generation high-efficiency combustion engines, the press release said.

The development team includes ORNL team leader Amit Shyam and ORNL’s J. Allen Haynes, Yukinori Yamamoto, Dongwon Shin, Adrian Sabau, Lawrence Allard, Thomas Watkins, Wallace Porter, James Morris, Shibayan Roy, Philip Maziasz, Dana McClurg, Charles Hawkins, Patrick Shower, and Brian Milligan; Fiat Chrysler’s Gregg Black, Chris Glaspie, Seyed Mirmiran, Yi Liu, and Lin Zhang; and Nemak’s Andres Fernando, Jose Talamantes, and Jose Alejandro Gonzalez.

Funding for this project was provided by the DOE’s Energy Efficiency and Renewable Energy Office, Office of Vehicle Technologies.

Additively Printed High Performance Magnets were developed by a team of researchers from ORNL and co-developed by Ames Laboratory Critical Materials Institute (CMI), Magnet Applications Incorporated, Tru-Design, and Momentum Technologies.

Additively Printed High Performance Magnets are the first rare earth bonded magnets created using the Big Area Additive Manufacturing method, allowing for rapid production with no size or shape limitations and minimal material waste. In contrast to more common sintered magnets that require the application of very high pressure to chemically reactive materials, bonded magnets are less expensive and resource-intensive to produce, the press release said.

The magnet feedstock blends a magnetic powder with a nylon polymer, and the finished magnets demonstrate comparable or better magnetic, mechanical, and microstructural properties than bonded magnets created with traditional injection molding methods. Using the BAAM system reduces energy consumption, lowers production costs, and conserves rare earth elements, which are widely used in electronics and are mined and processed overseas.

The development team, led by ORNL’s Parans Paranthaman, includes Vlastimil Kunc, Ling Li, Brian Post, Orlando Rios, Michael McGuire, Brian Sales, Edgar Lara-Curzio, and Amy Elliot, all of ORNL; Ames CMI’s Alex King, Thomas Lograsso, and Ikenna Nlebedim; John Ormerod and Robert Fredette of Magnet Applications Incorporated; Rick Spears of Tru-Design; and Preston Bryant of Momentum Technologies.

This project was supported by the DOE’s Critical Materials Institute, an Energy Innovation Hub funded by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office.

Filler Materials for Welding and 3D Printing were developed by ORNL in collaboration with the U.S. Army Tank Automotive Research, Development and Engineering Center.

The heating and melting processes of welding and metal additive manufacturing generates localized distortions and residual stresses in steel and other materials. These defects can cause the material to become brittle or crack, which can lead to catastrophic structural failure.

ORNL’s innovative filler materials counterbalance how much the materials expand and shrink and control the residual stress and distortion of high-strength steel structures. The filler materials also do not require the costly, labor-intensive heat treatments normally needed to avoid cracking and material embrittlement, providing significant economic benefits while improving the stability and durability of welded and 3D printed structures. In the future, these materials could revitalize the nation’s aging infrastructure and help avoid the human, environmental and financial impacts of massive structural failures.

The development team includes ORNL’s Zhili Feng, Xinghua Yu, Stan David, and Yanli Wang, and the U.S. Army’s Demetrios Tzelepis, Richard Gerth, James Anderson, and James Douglas.

This project was funded by the DOE’s EERE Office of Vehicle Technologies, the EERE Office of Fuel Cell Technologies, and a Work for Others Agreement with the U.S. Army.

Safe Impact Resistant Electrolyte (SAFIRE) was developed by a team of ORNL researchers and co-developed by the University of Rochester.

ORNL’s Safe Impact Resistant Electrolyte (SAFIRE) improves the safety of plug-in electric vehicle batteries.

In typical automotive lithium-ion batteries, the liquid electrolyte, which conducts the electrical current, poses a fire risk in high-speed collisions and requires heavy protective shielding, decreasing the vehicle’s range and efficiency. SAFIRE eliminates this risk by using an additive that transforms the liquid electrolyte to a solid upon impact. By blocking contact between electrodes, it prevents short circuiting and a potential fire. SAFIRE performs as well as conventional electrolytes under normal conditions and can significantly reduce electric vehicle weight and increase travel distance.

The development team included leader Gabriel Veith and Beth Armstrong, Hsin Wang, Sergiy Kalnaus, and Nancy Dudney, all of ORNL, and Wyatt Tenhaeff of the University of Rochester.

SAFIRE was funded by ORNL Seed Money and the DOE’s Advanced Research Projects Agency – Energy.

The dropletProbe Surface Sampling System for Mass Spectrometry was developed by ORNL researchers in coordination with SepQuant.

The dropletProbe system is a completely new means of surface sampling for mass spectrometry, a major scientific technique for measuring the masses of chemicals in a sample. The dropletProbe system provides rapid, simple chemical extraction and analysis for a host of scientific applications.

The system utilizes a liquid junction between the device and a surface to obtain samples for high-performance liquid chromatography and mass spectrometry analysis. It is a low cost, low maintenance and nondestructive method for sampling complex analytical surfaces, such as biological tissue samples with a high degree of precision. By reducing cost and improving accuracy, this tool should help increase the pace of scientific discovery.

The development team included Vilmos Kertesz and Gary Van Berkel of ORNL and Matt Orcutt and Alain Creissen of SepQuant.

This project was funded by the DOE’s Office of Science.

ACE: The Ageless Aluminum Revolution was submitted by the DOE’s Critical Materials Institute and was co-developed by ORNL, Eck Industries, Ames Laboratory, and Lawrence Livermore National Laboratory.

Lightweight materials like aluminum alloys can help substantially increase the efficiency of vehicles and airplanes. ACE is a new family of aluminum alloys that exhibits better performance at high temperature, is easier to cast than previous alloys, and does not require a heat treatment. By combining aluminum and cerium, or a similar element, with traditional alloying materials, ACE is able to demonstrate high mechanical performance and resist corrosion.

ACE alloys remain stable at temperatures 300 degrees Celsius higher than leading commercial alloys and can withstand 30 percent more load before they deform. Manufacturers can successfully cast ACE alloys in a wide variety of structural components without energy-intensive heat treatments, which could significantly increase production output and reduce manufacturing costs, in some cases by almost 60 percent.

The development team from ORNL was led by Orlando Rios and includes Zach Simms, Eric Stromme, Michael Kesler, Hunter Henderson, and Bruce Moyer. Other team members are Alex King of the Critical Materials Institute and Jonathan Lee, Patrice Turchi, Aurelien Perron, Alex Baker, and Scott McCall of Lawrence Livermore National Laboratory, and Ryan Ott of Ames Laboratory.

This project was funded by the DOE’s Critical Materials Institute, the EERE Advanced Manufacturing Office and a partnership with Eck Industries.

Dfnworks: A Computational Suite for Flow and Transport in Subsurface Fracture Networks was submitted by Los Alamos National Laboratory and co-developed with ORNL’s Scott Painter.

dfnWorks is a software suite that generates three-dimensional models of fractures in rocks and how fluids move through those fractures. Research in hydraulic fracturing, safe nuclear waste disposal and underground carbon dioxide storage rely on this type of software. The models can be incredibly complex and often require a great deal of computational time and power to run.

Compared with similar programs, dfnWorks requires less time to run and allows scientists to model geological conditions they could not previously. Scientists have used the software to model a variety of systems from a few millimeters up to entire kilometers in size.

Coating Solutions for Large-Format Additive Manufacturing was submitted by Tru-Design and co-developed with ORNL and Polynt Composites.

Large-scale 3Dprinting can quickly produce prototypes and molds used to manufacture parts, but these pieces are often neither smooth nor vacuum tight. As a result, manufacturers can’t use these molds, limiting the usefulness of 3D printing.

The Large Format Additive Coasting Solutions, TD Coat RT and TD Seat HT, minimize this problem. They cover the rough exterior of a printed part and create an unbroken vacuum-tight seal. The coatings can be machined and finished for manufacturing tools and molding applications at a fraction of the cost of traditionally tooled metal parts.

The ORNL development team was led by Vlastimil Kunc and included Craig Blue, Bill Peter, Lonnie Love, Brian Post, Ahmed Hassen, John Lindahl, David Nuttall, Chad Duty, and Nadya Ally.

The project received support from DOE’s EERE Advanced Manufacturing Office.

Techmer engineered additive manufacturing materials (TEAMM) were submitted by Techmer PM and co-developed with ORNL and BASF.

Techmer Engineered Additive Manufacturing Materials are new filled plastic carbon fiber compounds that are especially designed for 3D printing. Using 3D printing and an autoclave, manufacturers can use these materials to produce molds for high-performance composite panels and parts.

The company offers two different types of TEAMM with different proportions of carbon fiber, 25 and 50 percent, to provide a variety of mechanical properties for a range of applications. Using these compounds with an autoclave, aerospace companies can produce molds for a tenth of the cost and lead time compared to existing technology. Other applications include defense and high-end automotive markets.

The ORNL development team was led by Vlastimil Kunc and included Craig Blue, Bill Peter, Lonnie Love, Brian Post, Ahmed Hassen, John Lindahl, David Nuttall and Alex Roschli.

The project received support from DOE’s EERE Advanced Manufacturing Office.

ORNL is managed by UT-Battelle for the Department of Energy’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. For more information, visit http://science.energy.gov/.

More information will be added as it becomes available.

Do you appreciate this story or our work in general? If so, please consider a monthly subscription to Oak Ridge Today. See our Subscribe page here. Thank you for reading Oak Ridge Today.

Copyright 2017 Oak Ridge Today. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed.

Leave a Reply