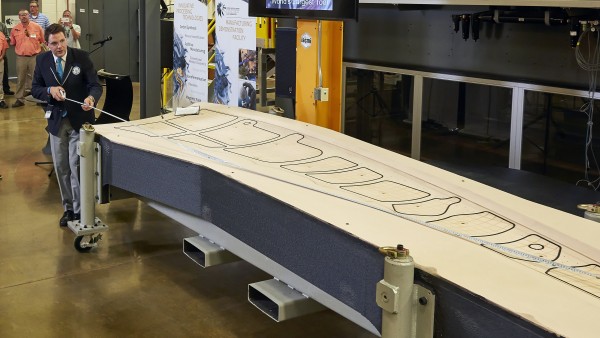

U.S. Energy Secretary Rick Perry takes a picture of the submersible hull 3D-printed for the U.S. Navy at the Oak Ridge National Laboratory Manufacturing Demonstration Facility in Hardin Valley on Monday, May 22, 2017. (Photo by John Huotari/Oak Ridge Today)

The U.S. Navy teamed up with Oak Ridge National Laboratory to print the military’s first 3D-printed submersible hull in just four weeks. The parts were printed in just days, rather than weeks, and production costs were cut by 90 percent.

The hull was printed at ORNL’s Manufacturing Demonstration Facility in Hardin Valley through a partnership with the Navy’s Disruptive Technology Lab, according to a story published July 20 by the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy. ORNL is a DOE laboratory.

“ORNL and the Navy saw this is as an opportunity to bring together their resources and expertise in a partnership with the potential to revolutionize manufacturing in the defense sector,” the DOE story said. “Not only can the Navy find new ways to reduce traditional costs associated with manufacturing, but the lessons learned from this project will help ORNL further explore 3D printing applications in the boating industry, aerospace, buildings, and anything that requires a large, resilient structure. Partnerships like these help drive economic growth and reinforce our national security.”

The team working on the 3D-printed submersible hull needed to create a 30-foot proof-of-concept hull out of carbon fiber composite material, DOE said. The prototype vessel is called the Optionally Manned Technology Demonstrator, and it could be used to deploy logistics capabilities and sensors. Future vessels will need to be manufactured faster and incorporate new designs to support Navy missions, DOE said. [Read more…]