Three-time Tour de France champion Greg LeMond, right, chairman and co-CEO of LeMond Companies, which owns LeMond Composites, tours ORNL’s Carbon Fiber Technology Facility. (Image courtesy of Oak Ridge National Laboratory, U.S. Department of Energy)

A new carbon fiber company that includes three-time Tour de France champion Greg LeMond plans to build a carbon fiber production line in west Oak Ridge to make composites for use in transportation, renewable energy, and infrastructure, and LeMond thinks the Knoxville area will become the world hub for carbon fiber.

The new company, LeMond Composites, has signed a licensing agreement with Oak Ridge National Laboratory, and it has purchased the former Theragenics building at Horizon Center, where CVMR, an international company that uses ore concentrates to create pure metal powders, had once planned to locate its headquarters and research and development.

LeMond Composites closed on the property, which includes about 21 acres, on July 21 for $5.4 million. It’s right next to ORNL’s Carbon Fiber Technology Facility, or CFTF, at Horizon Center. Renovations at the former Theragenics building are already under way.

Carbon fiber is light, stiff, and strong, a press release said. That makes it the perfect material for advanced composites in a variety of applications, including transportation, renewable energy, and infrastructure, the release said. It can be used to improve efficiency, save energy, and build or repair vehicles and planes, wind turbines and containers, and bridges and tunnels.

But the biggest obstacle to its widespread use has been its high cost.

Carbon fiber manufacturing pioneer Connie Jackson and a research team at ORNL’s Carbon Fiber Technology Facility have invented a breakthrough process that will reduce production costs by more than 50 percent compared to the lowest-cost industrial-grade carbon fiber, the press release said.

“Incredibly, this new carbon fiber has the mechanical properties of carbon fiber costing three times as much,” the release said. “Until now, manufacturing carbon fiber was an extremely energy-intensive process. This new method reduces energy consumed during production by up to 60 percent.”

It’s the most significant development in carbon fiber production in more than 50 years, and LeMond Composites, which was founded this year and is based in Oak Ridge, wants to introduce it to the global marketplace, the press release said.

“We can provide the advantages of our carbon fiber to many industries by improving strength, stiffness, and weight reduction,” said Jackson, who is now chief executive officer of LeMond Composites. “If you imagine replacing steel, aluminum, and fiberglass with our carbon fiber, you begin to understand the scope of the potential market. Our process will have global applications, and we are ready to move forward with scaling the technology.â€

The company’s licensing agreement with ORNL, a U.S. Department of Energy laboratory, will make LeMond Composites the first company to offer this new “industry-disrupting” carbon fiber, the press release said. Jackson and several of her ORNL teammates joined the company this year.

“We have assembled the only team in the world that has executed this proven technology, which uniquely positions us to deliver a successful outcome for our customers and stakeholders,†LeMond said. “From experience, I know that having the right team is a distinct business advantage.â€

LeMond is chairman and co-CEO of LeMond Companies, which owns LeMond Composites.

A new carbon fiber company that includes three-time Tour de France champion Greg LeMond plans to build a carbon fiber production line at the former Theragenics building at Horizon Center in west Oak Ridge to make composites for use in transportation, renewable energy, and infrastructure. (Photo by John Huotari/Oak Ridge Today)

The press release said the new manufacturing process will allow high-volume, cost-sensitive industries around the world to reap the benefits of carbon fiber composites at a fraction of the cost while incorporating chemistry geared toward recyclability.

“The development of this new process demonstrates the value of coupling basic and applied research, which is a hallmark of ORNL, and it underscores the Department of Energy’s commitment to addressing our nation’s most pressing energy challenges,†said Thom Mason, Oak Ridge National Laboratory director. “The Department’s sustained investments in scientific research and development and in specialized facilities such as CFTF are enabling a variety of applications that will lead to improvements in fuel efficiency and position U.S. industry for global success.â€

ORNL’s Carbon Fiber Technology Facility began operating in 2012, supported by the Department of Energy’s Advanced Manufacturing and Vehicle Technologies offices, to demonstrate the possibility of low-cost carbon fiber at a semi-production scale, the release said.

Growing demand from the automotive industry is due in large part to the global push to increase the fuel economy of nearly every vehicle produced, the press release said. In the United States, the demand is being driven by the Corporate Average Fuel Economy, or CAFE, standards. These standards demand a fleet-wide average fuel economy of 54.5 mpg by 2025. The single best way to improve fuel economy is to reduce the weight of the cars and their component parts, the release said.

“ORNL and Jackson’s remarkable breakthrough technology puts CAFE standards within reach, ensuring cost-effective weight reduction through the use of high-quality carbon fiber without sacrificing the strength and safety of the steel it replaces,” the press release said.

“We understand the growing demand from the automotive industry, and we are currently in negotiations with several of the world’s leading automotive brands and their suppliers,†LeMond said.

For the wind power industry, carbon fiber can be used to make turbine blades lighter and stiffer, thereby increasing efficiency. Previously, carbon fiber was too expensive for maximum use in this market.

Other sectors, including shipping, air travel, and marine, could see significant energy savings through the use of carbon fiber in the light weighting of their containers, planes, and ships, the press release said.

Carbon fiber composites can also be used to build, reinforce, or repair bridges, tunnels, and commercial and residential structures.

“As a result of the affordability of this carbon fiber, we believe that worldwide mass adoption will be inevitable,” LeMond said. “We are positioning ourselves to grow and meet this demand by locating our company in Tennessee—a state that through Governor Bill Haslam and Commissioner Randy Boyd’s forward-thinking programs like Tennessee Promise—will provide a steady stream of quality employees for our company. Our close proximity to ORNL adds a value beyond measure, and we are looking forward to future collaborations with them.

“Additionally, with the input of the University of Tennessee, the Institute for Advanced Composites Manufacturing Innovation, or IACMI, and the emerging composites corridor, I believe the Knoxville area will become the world hub for carbon fiber in the future. On a personal note, the bike riding in this area is incredible.â€

The new LeMond Composites building is at 103 Palladium Way. The company said the first commercially available product will be ready in the first quarter of 2018.

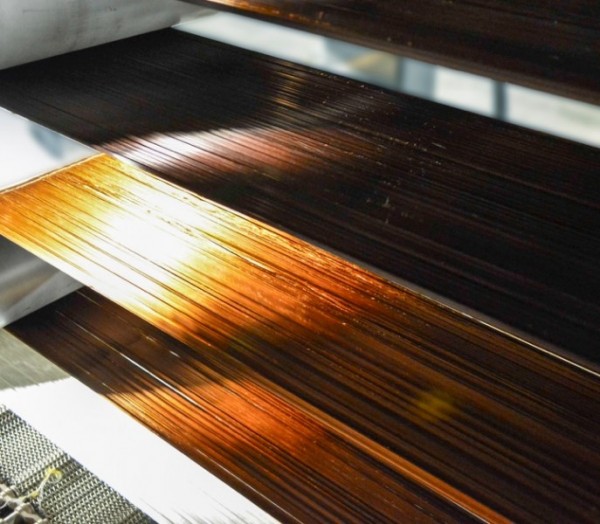

Carbon fiber production is pictured above. (Image courtesy of Oak Ridge National Laboratory, U.S. Department of Energy)

Carbon fiber production is pictured above. (Image courtesy of Oak Ridge National Laboratory, U.S. Department of Energy)

ORNL carbon fiber production is pictured above. (Image courtesy of Oak Ridge National Laboratory, U.S. Department of Energy)

Do you appreciate this story or our work in general? If so, please consider subscribing to Oak Ridge Today. See our Subscribe page here. Thank you for reading Oak Ridge Today.

More information will be added as it becomes available.

Copyright 2015 Oak Ridge Today. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed.

Angi Agle says

Awesome news!

johnhuotari says

I went by there Tuesday and there were workers in the building, and I was told that renovations are under way.