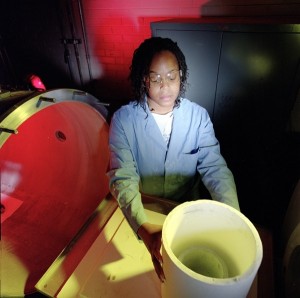

A microwave operator handles the crucible that holds the material as it is melted. Microwave technology is the preferred method for melting materials because of the ease of removing carbon impurities from the metal. (Photos courtesy B&W Y-12)

New microwaves that can melt metal and help remove carbon impurities from uranium could be used in the proposed Uranium Processing Facility at the Y-12 National Security Complex.

Y-12 doesn’t plan to use any of its traditional ovens, known as vacuum induction melters, or VIMs, in the UPF, officials said. Those ovens use electric currents and a magnetic field to melt metal.

But it’s easier to “float out” carbon impurities in microwaves because they don’t stir molten metals the way the traditional ovens do, Y-12 officials said. Carbon contaminants in uranium castings could be reduced by 30 percent.

Y-12 melts and casts uranium to combine it into hollow cylinders for storage, make parts for the nation’s nuclear weapons stockpile, and supply nuclear fuel for the U.S. Navy. Microwaves could eventually be used for all three tasks.

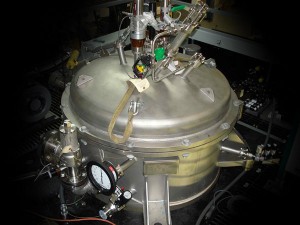

The plant has been experimenting with microwave technologies since the 1990s, and it has more than 50 patents on microwave technologies, said John Gertsen, Y-12 vice president for UPF integration, and Ellen Boatner, a Y-12 spokeswoman. The plant is now “fine-tuning” its production microwave.

“The microwave is being used in production on a limited basis,” Y-12 said in a statement Wednesday. “It is currently being used as part of a microwave prove-in plan that includes running various enrichments and alloys for final acceptance for full production use as well as input into UPF design parameters.”

Y-12’s production microwave is expected to improve purity in melted metal. The microwave recently received final approval for use in melting and casting materials.

Boatner said the microwave is now being used for basic casting, such as casting the uranium cylinders, or “logs.” She said VIMs are still used for complex casting.

In April, Gertsen said Y-12 has conducted more than 500 melts of different materials with microwaves and has been pleased with the lab results. In 2008, a prototype unit was introduced, and it had about 30 successful test runs.

Since then, Y-12 has started working on the production microwave, which is larger than those that were tested in the lab. There were some problems and delays, but workers finally got it to run right, Gertsen said. Among other things, they have worked on the right mold configurations for different shapes and angles, and to consistently create the same end products as those produced by the vacuum induction melters.

On Wednesday, Y-12 said it has proven the technology to the National Nuclear Security Administration, which oversees the site.

“It’s no longer a project,” Boatner said. “It is being released into production.”

Gertsen said the entire casting area could occupy less than one-tenth of the UPF, a proposed facility at Y-12 that could cost up to $6.5 billion, consolidate all uranium processing activities at the plant, and start operating in 2023. Casting is one of about a dozen major planned processes in the new building, which could be 350,000 square feet. Other areas would include machining, chemical processing, and subassembly.

Gertsen is confident that Y-12 will be able to use the microwaves at UPF.

“We don’t see showstoppers there,” he said.

Y-12 won’t discuss the number of production furnaces it uses. They come in different sizes, shapes, and configurations, and can melt other metals besides uranium.

Y-12 officials didn’t cite a major difference in the cost and power consumption of microwaves and VIMs. Boatner said the two types of ovens, when outfitted with similar instruments, cost about the same. And they use about the same amount of power. Boatner said microwaves use half the power of VIMs but apply it for twice as long, making the power usage “essentially a wash.”

The main reason for switching to the microwaves, she said, is their ability to help workers remove carbon impurities from metals.

“Carbon hurts the properties of uranium,” Boatner said.

Leave a Reply