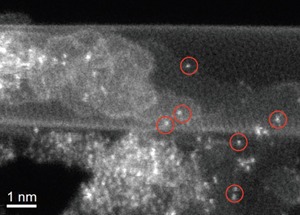

Electron microscopy at Oak Ridge National Laboratory confirmed that a carbon nanotube material that exhibits desirable chemical properties has many heavy atoms, such as the iron atoms circled in red. (Photo submitted by ORNL)

A team of researchers that included scientists from Oak Ridge National Laboratory has developed an inexpensive carbon nanotube material that could help lower the cost of fuel cells and catalytic converters.

The new material could provide a substitute for expensive platinum catalysts.

A precious metal, platinum has long been prized for its ability to spur chemical reactions in a process called catalysis, but at more than $1,000 an ounce, its high price is a limiting factor for applications like fuel cells, which rely on the metal, an ORNL press release said.

Searching for an inexpensive alternative, the research team turned to carbon, one of the most abundant elements, the press release said. Led by Stanford University’s Hongjie Dai, the team developed a multi-walled carbon nanotube complex that consists of cylindrical sheets of carbon.

“Once the outer wall of the complex was partially ‘unzipped’ with the addition of ammonia, the material was found to exhibit catalytic properties comparable to platinum,” the release said. “Although the researchers suspected that the complex’s properties were due to added nitrogen and iron impurities, they couldn’t verify the material’s chemical behavior until ORNL microscopists imaged it on an atomic level.”

ORNL microscopic analysis confirmed that the nitrogen and iron elements were incorporated into the carbon structure. The next step for the team is to understand the relationship between the nitrogen and iron to determine whether the elements work together or independently.

The team’s findings are published in Nature Nanotechnology. Coauthors on the paper are ORNL’s Stephen Pennycook and Juan-Carlos Idrobo; Vanderbilt University’s Wu Zhou, Stanford’s Yanguang Li, Hailiang Wang, Liming Xie and Yongye Liang; and Tsinghua University’s Fei Wei.

Research was carried out in part at the Shared Equipment Research Facility (ShaRE), a user facility supported by the U.S. Department of Energy, Office of Science; and by the Materials Sciences and Engineering Division in DOE’s Office of Basic Energy Sciences.

Leave a Reply