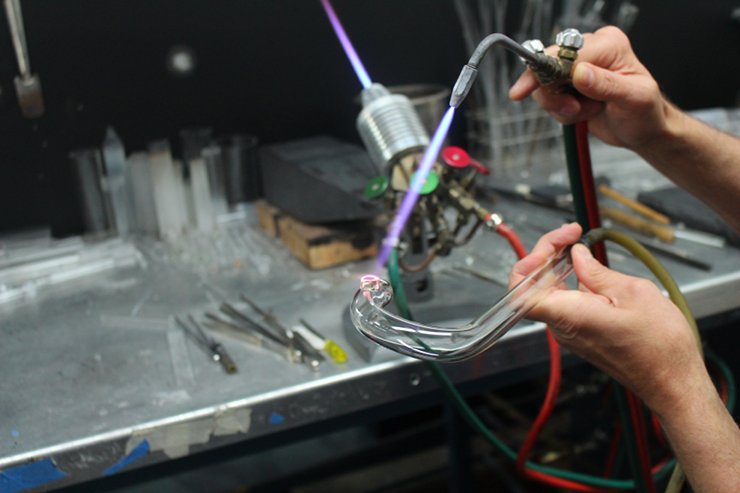

When people think of glass blowing, they think of unique vases and colorful works of art made in places like Dollywood or Asheville. Not many people know that Oak Ridge has its very own scientific glass blowers working for the Oak Ridge National Laboratory.

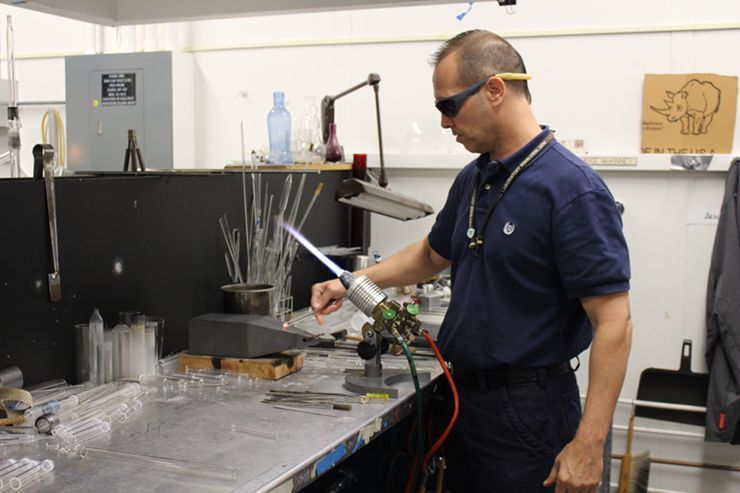

ORNL has its own glass shop on site. Scientific Glassblower and Shop Manager Jason Craig has been blowing glass for almost 25 years.

According to Craig, ORNL has always had a glass shop. The glass shop now has been in its current building since 1955. There used to be 10 glass blowers at ORNL, and two or three at the Y-12 National Security Complex. Now Craig and Carlos Rodriguez-Flores are the two full-time glassblowers, with a retired glass blower who comes in part-time.

Craig started out as an artistic glass blower before transitioning to scientific glass blowing.

ÔÇťWorking in a (glass shop) at a research facility is much different than blowing glass in a production shop or for artistic glass blowing,” Craig said during an interview in the ORNL glass shop last week. “So, I guess my greatest challenge is just trying to…keep track of the customers and the jobs and ordering materials, inventory, and gas cylinders, and all that stuff…WeÔÇÖre basically running our own business here inside the laboratory.”

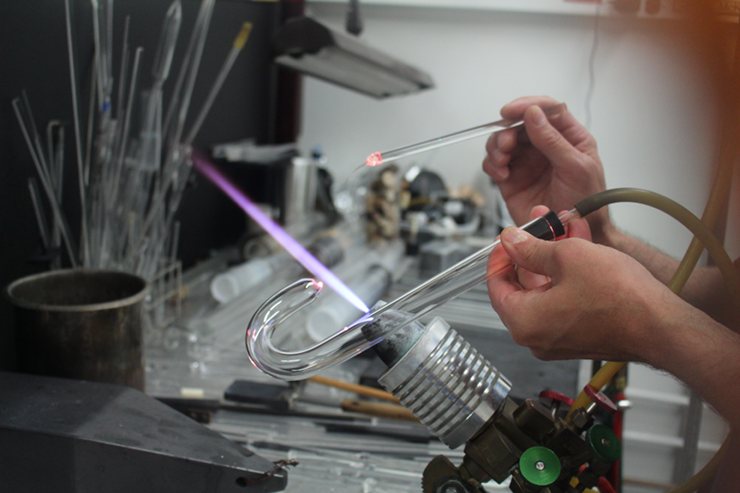

Most of the items that the shop makes are custom orders from researchers for specific experiments. The glass shop is the main source for these custom orders.

ÔÇťAs far as the custom stuff thatÔÇÖs used out here, itÔÇÖs probably almost 100 percent us,ÔÇŁ Craig said.

Most of the basic measuring equipment used by the lab, such as beakers and test tubes, are ordered out of a catalog. However, the glassblowers will occasionally make adjustments to those already purchased products.

The glass shop receives anywhere between six and 15 orders a week. Most of their customers are ORNL employees, and a small number are from the University of Tennessee. They can do outside work, but they try to steer away from it due to large amounts of paperwork.

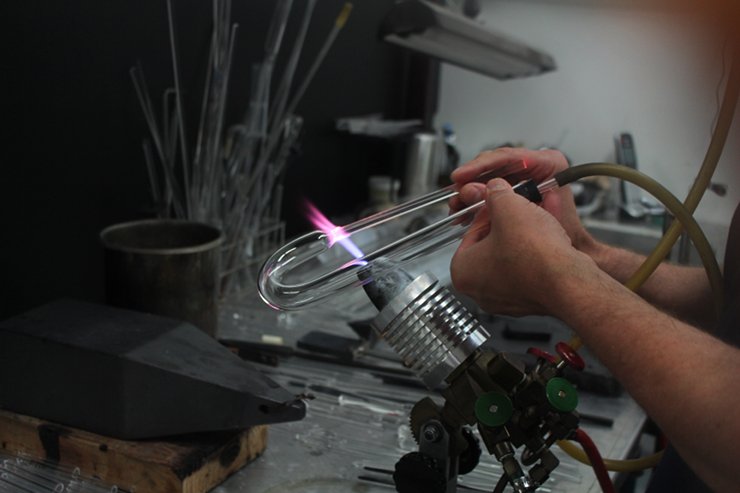

The types of glasses they work with include borosilicate, silica (quartz), and aluminosilicate glass. They only rarely work with soft glass, which is what the windows from your house are made from. They use different materials depending on what the experiment entails.

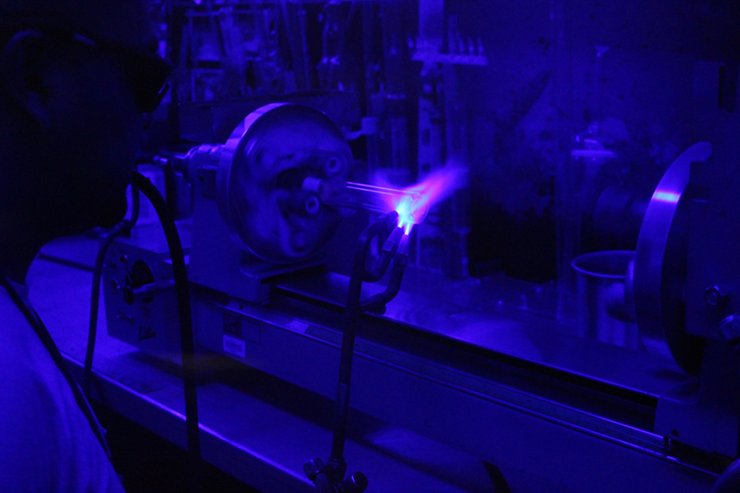

For example, they use only aluminosilicate in SNS, or Spallation Neutron Source. Borosilicate glass blocks the neutrons and the quartz glass allows their helium to leak out, so aluminosilicate solves both of those problems.

ÔÇťFor normal lab apparatus we use borosilicate glass…you get into quartz when youÔÇÖre doing high temperature stuff. Anything over 500 degrees Celsius, you need quartz,” Craig said. “If they are used in certain chemicals that react badly with borosilicate glass, then you use quartz…The soft glass we donÔÇÖt really use much.”

The glass shop is a major asset to the lab in terms of time and convenience.

Much of the work at the lab, especially the nuclear work, needs to be done in a timely manner. Having the glass shop at the lab allows the glass blowers to work directly with the researcher to figure out their needs and give them exactly what they want.

ÔÇťSome of the stuff we do is putting handles on flasks and tools and stuff so that they can be used in hot cells,” Craig said. “So, a lot of that stuff needs to be done by people who are on site who can communicate effectively with the researchers to figure out exactly what they need.”

Contacting an outside company would involve sending a drawing out, having the company look at the drawing, making modifications, sending the drawing back, and doing that a few times. This process becomes longer if the initial design does not work, and they must send it back for modifications.

ÔÇťOffering the researchers this service in a timely manner I think is the most important thing,ÔÇŁ Craig said.

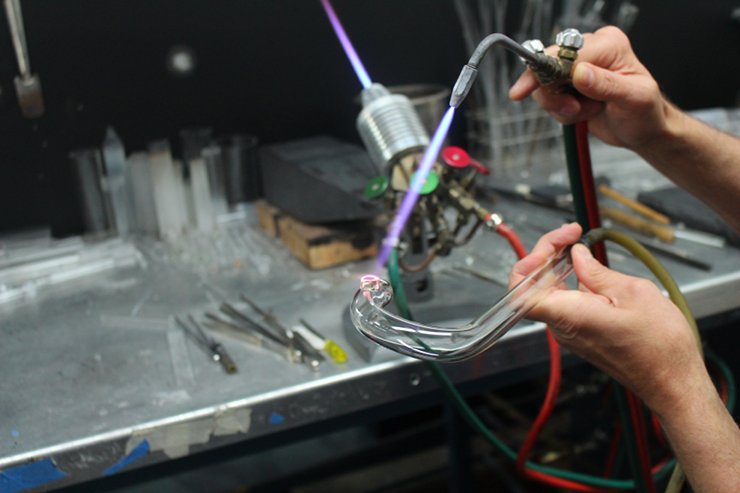

The close proximity of the shop is not only beneficial for creating new products quickly, but also for fixing broken products.

ÔÇťSomeone has a rush job that comes in. They need something immediately. Something breaks and their experiment is counting on that. They come right in, and weÔÇÖre able to just say: ÔÇśAlright, youÔÇÖre in trouble. We want to help you out,ÔÇÖÔÇŁ Rodriguez-Flores said.

ÔÇťIt might just be a tube thatÔÇÖs cracked on one end or something thatÔÇÖs a little too long and they canÔÇÖt use it, so we cut it off or repair it…It could take a week or two to do if you had to send it out, but we can do it the same day,ÔÇŁ Craig said.

One challenge that the glass blowers face is accuracy. The fact that all the products are hand-made makes it more difficult to ensure that certain products are the exact same size. However, the glass blowers work hard to make their products as accurate as possible.

ÔÇťWe have tolerances in here sometimes to a tenth of a millimeter or a quarter of a millimeter depending on the process,” Craig said. “Whether thatÔÇÖs cutting something or blowing a piece of glass that size. Some dimensions are easier or more difficult to hold than others…and it all depends on the customer and what theyÔÇÖre going to use it for as to how critical those tolerances are. Sometimes they need to be ‘dead on,’ and sometimes it could just be ÔÇśabout this long.ÔÇÖÔÇŁ

Another challenge the glassblowers face is making sure they have a good understanding of the scientistsÔÇÖ needs.

ÔÇťSometimes they explain to us what they want, but weÔÇÖre really not sure exactly what they want so…we have to figure out exactly what they want,ÔÇŁ Rodriguez-Flores said.

ÔÇťSometimes theyÔÇÖre not sure what they want,ÔÇŁ Craig said.

The challenge to meet each scientistsÔÇÖ needs forces the glassblowers grow and learn with each order, and they get to create products for a variety of different experiments.

ÔÇťThatÔÇÖs one nice thing about working in the glass shop at Oak Ridge…weÔÇÖre exposed to all different fields of research so we get to talk to a lot of people about what theyÔÇÖre doing,” Craig said. “TheyÔÇÖre usually excited to talk about it, and so weÔÇŽget to see a little bit of everything, whereas most people are in their groups doing their work and they donÔÇÖt get to see whatÔÇÖs going on with the lab as a whole. Whereas we get exposed to a lot of good stuff.”

There does not seem to be much awareness about scientific glass blowing as a career. According to Craig, there is only one school in the nation that offers a degree in scientific glass blowing, and it is in southern New Jersey.

ÔÇťExposure to glass blowing, be it scientific or artistic, would be great for people to see…everybody gets to see painting, and tri painting, sculptures with clay…But not many people get to see glass blowing firsthand,ÔÇŁ Craig said.

See more photos here.

See videos here.

Kate Trabalka is a media and communications student who is concentrating on journalism at East Tennessee State University and helping Oak Ridge Today with stories and photos this summer.

More information will be added as it becomes available.

You can contact John Huotari, owner and publisher of Oak Ridge Today, at (865) 951-9692 or john.huotari@oakridgetoday.com.

Most news stories on Oak Ridge Today are free, brought to you by Oak Ridge Today with help from our advertisers, sponsors, and subscribers. This is a free story. Thank you to our advertisers, sponsors, and subscribers. You can see what we cover here.

Do you appreciate this story or our work in general? If so, please consider a monthly subscription to Oak Ridge Today. See our Subscribe page here. Thank you for reading Oak Ridge Today.

Copyright 2019 Oak Ridge Today. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed.

Leave a Reply