Guinness World Records Judge Michael Empric, left, is pictured above with Bill Peter, director of ORNL’s Manufacturing Demonstration Facility in Hardin Valley, after Empric had confirmed that a trim-and-drill tool made at the MDF for Boeing (it’s partially pictured in the foreground) had set the world record for largest solid printed 3D item on Monday, Aug. 29, 2016. (Photo by John Huotari/Oak Ridge Today)

A tool made by Oak Ridge National Laboratory has set a world record for largest solid item manufactured on a 3D printer. Guinness World Records confirmed the tool’s measurements during a visit to ORNL’s Manufacturing Demonstration Facility in Hardin Valley on Monday.

Here are pictures from the Monday morning award ceremony by John Huotari of Oak Ridge Today and ORNL/U.S. Department of Energy.

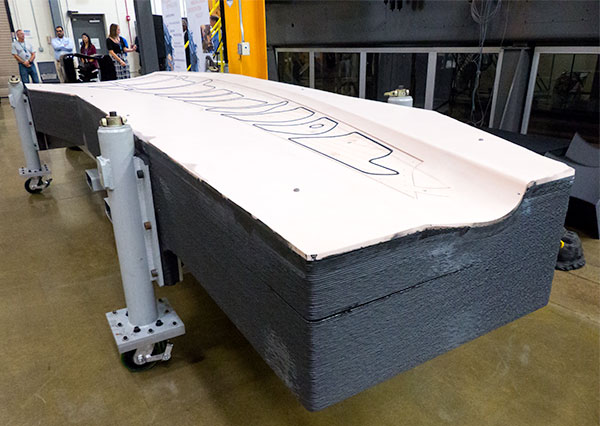

The trim-and-drill tool measures 17.5 feet long, 5.5 feet wide, and 1.5 feet tall. It’s comparable in length to a large sport utility vehicle and weighs approximately 1,650 pounds.

It will be used to help make a wing part on the Boeing 777X airplane, a passenger jet. After ORNL completes some testing, Boeing will evaluate the tool in the company’s new production facility in St. Louis and then provide information to ORNL about its performance.

ORNL printed the trim-and-drill tool in only 30 hours on a 3D printer at the Manufacturing Demonstration Facility in Hardin Valley using mostly ABS (acrylonitrile butadiene styrene) mixed with about 20 percent carbon fiber. ABS is the same material used to produce Legos, and it’s a tough, strong polymer, said Bill Peter, MDF director.

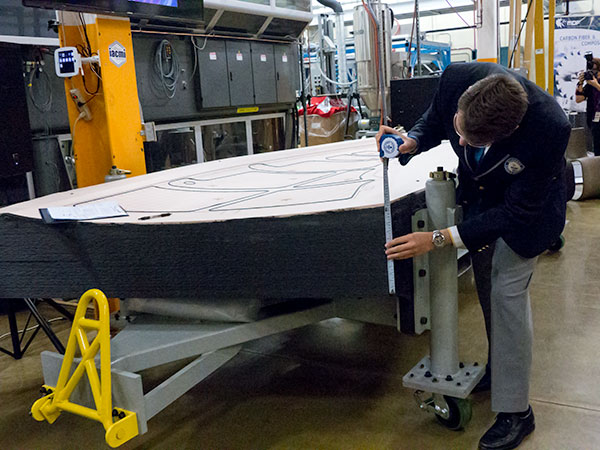

Judge Michael Empric said Guinness World Records had set a minimum measurement of 10.5 cubic feet for the new largest solid 3D printed item, which is a new category. The Boeing tool printed by ORNL measured much larger, 82.4 cubic feet, Empric said.

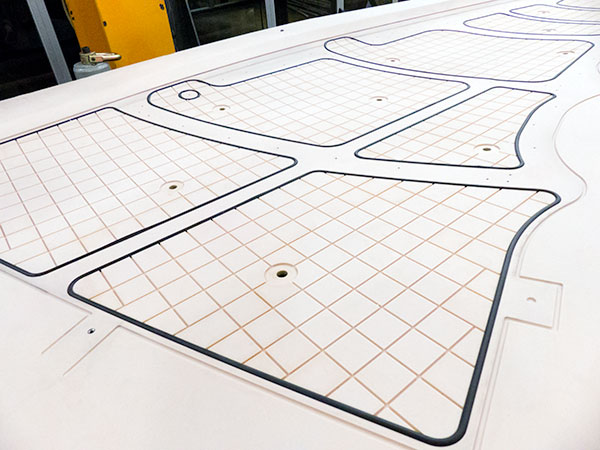

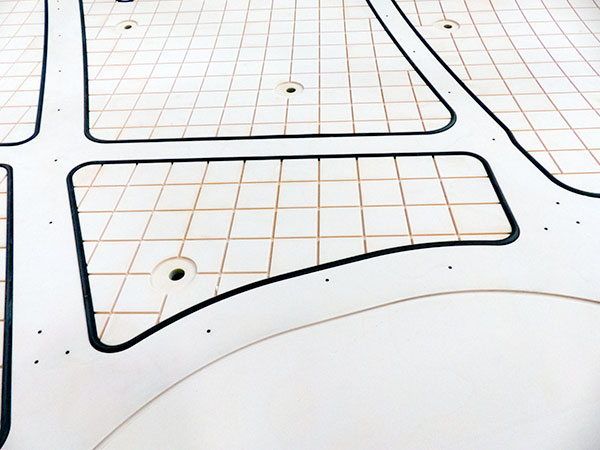

A 3D printed tool that will be used for trimming and drilling a wing part for Boeing 777X passenger jets was printed in Hardin Valley by ORNL, and it has received the title of largest solid 3D printed item by Guinness World Records. (Photo by John Huotari/Oak Ridge Today)

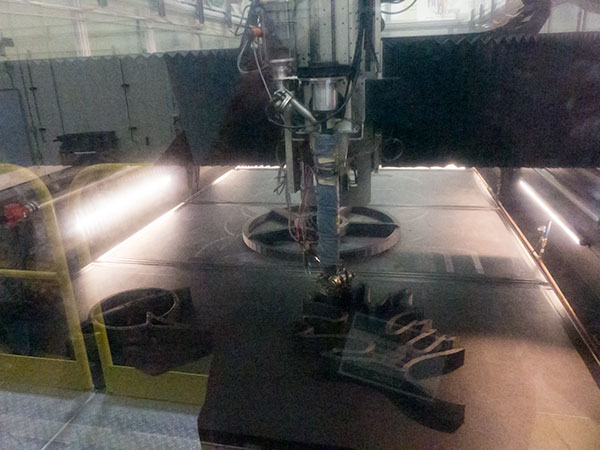

A Cincinnati BAAM 3D printer is pictured above from a video still manufacturing the trim-and-drill tool for Boeing at ORNL’s Manufacturing Demonstration Facility in Hardin Valley. The tool will be used to help make a wing part for the 777X passenger jet, and it has set a Guinness World Record for largest solid printed 3D item. (Photo by John Huotari/Oak Ridge Today)

A 3D printed tool that will be used for trimming and drilling a wing part for Boeing 777X passenger jets was printed in Hardin Valley by ORNL, and it has received the title of largest solid 3D printed item by Guinness World Records. The trim-and-drill tool has a vacuum system to seal the trailing-edge wing part to the tool to prevent the part from moving during drilling and trimming. (Photo by John Huotari/Oak Ridge Today)

Guinness World Records Judge Michael Empric, right, is pictured above with ORNL Director Thom Mason after a tool 3D printed by Oak Ridge National Laboratory for use on the Boeing 777X passenger jet won the title of largest solid 3D printed item on Monday, Aug. 29, 2016. (Photo by John Huotari/Oak Ridge Today)

Guinness World Records Judge Michael Empric, right, is pictured above with Leo Christodoulou, chief engineer for materials and manufacturing technology in Boeing Research and Technology, after a tool 3D printed by Oak Ridge National Laboratory for use on the Boeing 777X passenger jet won the title of largest solid 3D printed item on Monday, Aug. 29, 2016. (Photo by John Huotari/Oak Ridge Today)

Official measurement of the 3D printed trim tool co-developed by Oak Ridge National Laboratory and the Boeing Company exceeded the required minimum size to achieve the Guinness World Records title of largest solid 3D printed item. Pictured above on Monday, Aug. 29, 2016, is Guinness World Records Judge Michael Empric. (Photo courtesy ORNL, U.S Department of Energy)

A 3D printed tool that will be used for trimming and drilling a wing part for Boeing 777X passenger jets was printed in Hardin Valley by ORNL, and it has received the title of largest solid 3D printed item by Guinness World Records. (Photo by John Huotari/Oak Ridge Today)

A 3D printed tool that will be used for trimming and drilling a wing part for Boeing 777X passenger jets was printed in Hardin Valley by ORNL, and it has received the title of largest solid 3D printed item by Guinness World Records. (Photo by John Huotari/Oak Ridge Today)

Guinness World Records Judge Michael Empric awarded the title of largest solid 3D printed item on Monday, Aug. 29, 2016, to ORNL Laboratory Director Thom Mason, Leo Christodoulou from The Boeing Company, ORNL’s Vlastimil Kunc, and Mike Matlack from Boeing. They are in front of the tool and the 3D printer used to make it at ORNL’s Manufacturing Demonstration Facility in Hardin Valley. (Photo courtesy ORNL, U.S. Department of Energy)

Guinness World Records Judge Michael Empric measures the trim-and-drill tool made for Boeing by ORNL at the Manufacturing Demonstration Facility in Hardin Valley. The tool will be used for a wing part on the 777X passenger jet, and it set a world record for largest solid 3D printed item on Monday, Aug. 29, 2016. (Photo by John Huotari/Oak Ridge Today)

Guinness World Records Judge Michael Empric measures the trim-and-drill tool made for Boeing by ORNL at the Manufacturing Demonstration Facility in Hardin Valley. The tool will be used for a wing part on the 777X passenger jet, and it set a world record for largest solid 3D printed item on Monday, Aug. 29, 2016. (Photo by John Huotari/Oak Ridge Today)

Guinness World Records Judge Michael Empric measures the trim-and-drill tool made for Boeing by ORNL at the Manufacturing Demonstration Facility in Hardin Valley. The tool will be used for a wing part on the 777X passenger jet, and it set a world record for largest solid 3D printed item on Monday, Aug. 29, 2016. (Photo by John Huotari/Oak Ridge Today)

A 3D printed tool that will be used for trimming and drilling a wing part for Boeing 777X passenger jets was printed in Hardin Valley by ORNL, and it has received the title of largest solid 3D printed item by Guinness World Records. The trim-and-drill tool has a vacuum system to seal the trailing-edge wing part to the tool to prevent the part from moving during drilling and trimming. (Photo by John Huotari/Oak Ridge Today)

The Cincinnati Inc. BAAM (Big Area Additive Manufacturing) machine prints an oak leaf for Oak Ridge National Laboratory, right, and Boeing logo, left, on Monday, Aug. 29, 2016. (Photo by John Huotari/Oak Ridge Today)

See our story on the ORNL-Boeing Guinness World Record here.

Do you appreciate this story or our work in general? If so, please consider subscribing to Oak Ridge Today. See our Subscribe page here. Thank you for reading Oak Ridge Today.

Copyright 2016 Oak Ridge Today. All rights reserved. This material may not be published, broadcast, rewritten, or redistributed.

Leave a Reply